At Tolerance Masters, we manufacture impellers and wheels in custom configurations to meet the exact requirements of your specifications. As an ISO 9001:2008 and AS9100D certified provider of precision machined products, we have the specialized skills for producing exceptional quality products that meet or exceed your performance objectives.

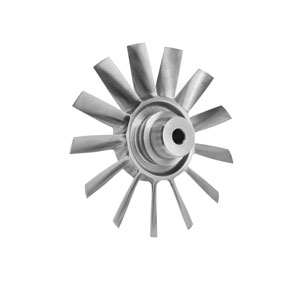

As a company dedicated to advanced machining, we use a sophisticated set of processes to create impellers and turbine wheels measuring up to 15” in diameter with concave or convex blade geometries. For close tolerance parts with geometrically complex shapes, we offer 5-axis “hog-out” machining for low to medium volume production. This process allows us to produce high precision, structurally strong parts within a short period of time. For impellers and wheels with configurations that would be difficult to machine, we produce castings or forgings to near net shape for finish machining

We manufacture impellers and wheels for leading companies in the aerospace, defense, transportation, medical, and satellite systems industries. In addition to high temperature investment castings, we manufacture impellers from aluminum, stainless steel, high-nickel alloys, and high-temperature metals. Complicated blade profile geometries and other intricate designs are repeatably produced with profile tolerances of ±0.001”.

Our manufacturing processes incorporate numerous quality checkpoints as well as rigorous final test and CMM inspection. By providing you with precisely accurate products, you are assured the pressure and flow objectives of your application are met.

Contact us today for more information about this family of products.