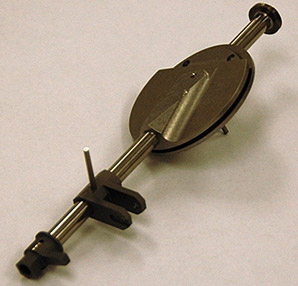

Machined out of Inconel 718, a high temperature alloy, Tolerance Masters constructed a series of butterfly disc and shaft assemblies to be used within an exhaust system for the aerospace industry. These products control bleed air flow from an auxiliary power unit (APU) on a business jet airframe. Our company was required to manufacture these units under an extremely tight deadline window. Quickly employing a variety of complex machining processes, Tolerance Masters was able to deliver an initial FA lot of eight pieces in less than four months!

Before the required four part assembly could take place, Tolerance Masters had to build all necessary components. The construction of the butterfly disc and mating shaft alone required many of our primary capabilities, including CNC turning, 5X milling, sphere & groove grinding, wire EDM, and lapping. All of these operations were performed in-house.

Next, we needed to equip the shaft with a carbide coating. But, before this coating could be properly applied, numerous grind operations were necessary in order to qualify the treated surfaces. Once the shafts were grounded and the coating was successfully applied, further grinding operations were performed using specifically designed diamond grind wheels. This supplementary grinding process was necessary in order to obtain a precise coating thickness of.006 inches. After grinding was complete, each unit was equipped with a final microfinish of 8rms.

Finally, once all components were successfully constructed, including the linkage and locking crank, we then assembled each unit, creating the final product. In order to properly align the hole locations against the butterfly disc with the mating shaft, we were required to design a unique assembly fixture to be used when performing the 4X milling operation. The manufacturing of the set pin holes also required specially designed taper reamer tools.

Using sophisticated machining and finishing techniques, Tolerance Masters was able to build a series of eight butterfly disc and shaft assemblies to be used by the aerospace industry. The process required us to build each component from scratch, using complex manufacturing processes, before we could begin the final assembly of each unit. And yet, despite the unique complexity of this operation, we were able to build quality product within a tight four-month turnaround time, meeting high client expectations.